Toilet partition parts work together to create functional, private restroom spaces. Each component plays a specific role in the overall system’s performance and longevity.

We at Partition Stalls see many facility managers struggle with selecting the right components for their projects. Understanding these essential parts helps you make informed decisions that save time and money.

Key Components of Toilet Partition Systems

Panels That Define Your Space

Panels form the backbone of any toilet partition system and directly impact user privacy and structural integrity. Standard panel heights range from 58 to 82 inches, with 72-inch panels providing optimal privacy for most commercial applications. One-inch thick panels offer superior stability compared to thinner alternatives in high-traffic environments. Door panels typically measure 24 inches wide, though 22-inch doors work better in compact restroom layouts. The gap between the floor and panel bottom should never exceed 12 inches to maintain privacy while allowing proper access for cleaning.

Hardware That Handles Daily Abuse

Hinges determine how smoothly doors operate and how long they last under constant use. Gravity hinges automatically close doors and enhance privacy in commercial restrooms. Stainless steel hinges outperform aluminum alternatives by 40% in corrosion resistance tests, which makes them the smart choice for moisture-heavy environments like pool facilities and gyms. Anti-grip headrails prevent users from climbing over stalls and reduce maintenance calls by 30% according to facility management studies.

Tamper-proof screws add security in public spaces (though they require special tools for maintenance access).

Latches That Protect Privacy

Latch mechanisms must balance ease of use with reliable privacy protection. Slide latches offer the most intuitive operation for users of all ages, while indicator latches provide visual occupancy signals that reduce awkward encounters. Emergency access latches allow facility staff to open doors when needed, but staff should test these monthly to verify proper function. Latch placement at 45 inches from the floor meets ADA requirements and accommodates wheelchair users effectively. Quality latches can operate smoothly for 8 to 15 years with proper maintenance, while cheap alternatives often fail within two years of installation.

Support Systems That Maintain Stability

Brackets and support systems keep partitions secure and prevent wobbling or movement during use. Wall brackets stabilize partitions at wall connections, while floor brackets secure the bottom portions to prevent tipping. Pilaster shoes at the base of support posts provide additional stability (any looseness can compromise the entire stall system). Double ear wall brackets work best for 1-inch installations, while single ear brackets suit various panel sizes effectively.

The materials you choose for these components directly affect their performance and lifespan in different environments.

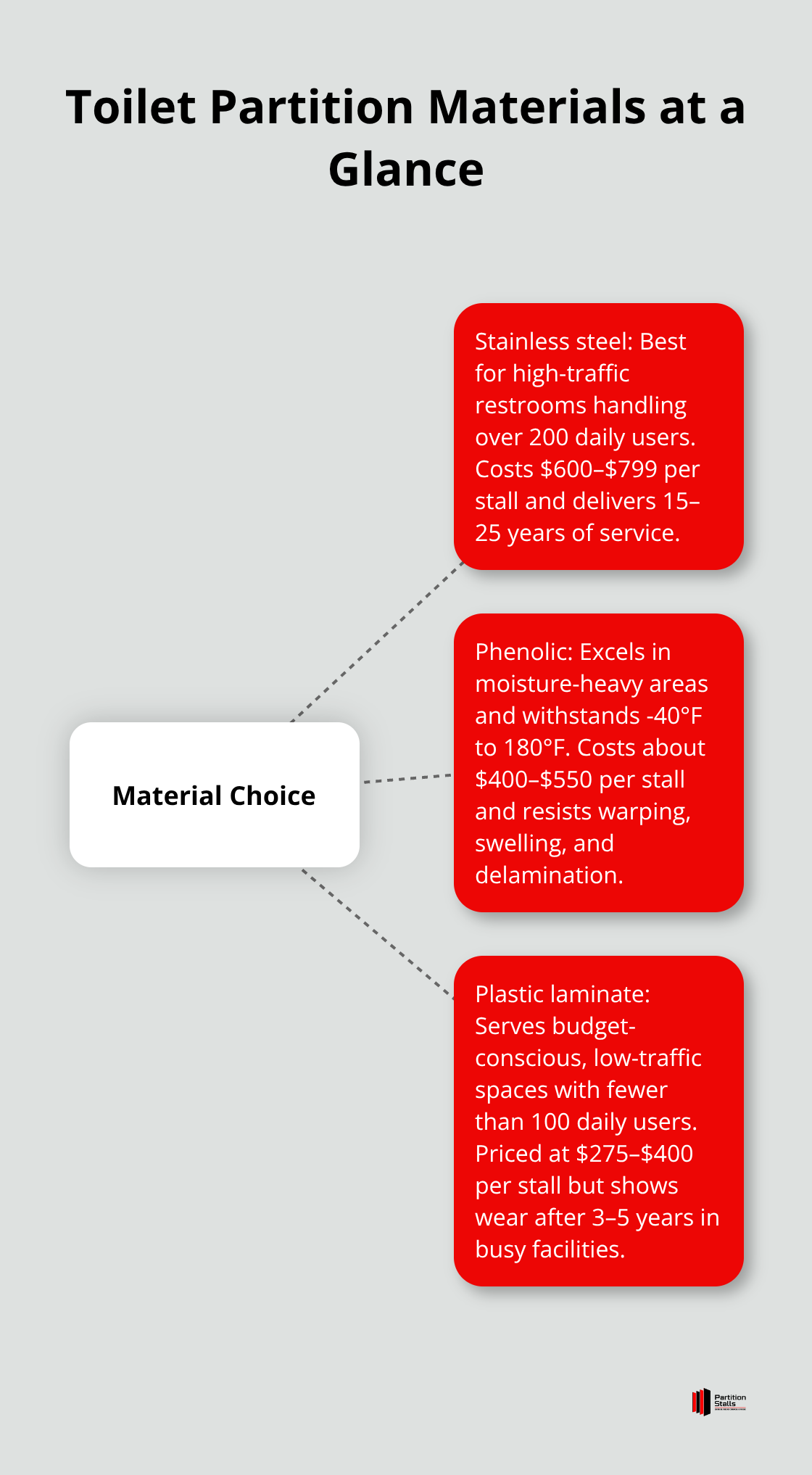

Materials Used in Toilet Partition Construction

Stainless Steel Delivers Unmatched Durability

Stainless steel stands as the ultimate material for high-traffic commercial restrooms, offering unmatched durability and superior performance. This material resists corrosion, scratches, and vandalism better than any alternative in facilities that handle over 200 daily users. Stainless steel partitions typically cost between $600 to $799 per stall but deliver 15 to 25 years of service life with minimal maintenance.

The material’s non-porous surface prevents bacteria growth and allows thorough sanitization with standard cleaning products. Fire ratings reach Class A levels, which makes stainless steel compliant with strict building codes for schools, airports, and healthcare facilities. Heavy-duty construction withstands daily abuse while maintaining its professional appearance throughout decades of use.

Phenolic Core Dominates Wet Environments

Phenolic partitions excel in moisture-heavy environments like pool areas, locker rooms, and outdoor facilities where other materials fail within months. This engineered material combines resin-impregnated kraft paper with decorative surface layers, which creates panels that resist swelling, warping, and delamination even under constant humidity exposure.

Phenolic partitions maintain structural integrity in temperatures that range from -40°F to 180°F (perfect for facilities with extreme climate variations). The material costs approximately $400 to $550 per stall and withstands high-humidity environments and frequent washdowns without warping or degrading. Chemical resistance protects against harsh cleaning agents and pool chemicals that destroy standard materials.

Plastic Laminate Serves Budget-Conscious Projects

High-pressure laminate partitions deliver acceptable performance at $275 to $400 per stall, which makes them suitable for low-traffic environments with tight budgets. These partitions work well in small office buildings, retail stores, and restaurants with fewer than 100 daily users. Laminate surfaces resist minor impacts and scratches but show wear patterns after three to five years in busy facilities.

The material offers decent moisture resistance for standard restroom humidity levels but fails in pool areas or outdoor installations. Regular maintenance every three months extends laminate partition life and maintains appearance standards. Color options and decorative patterns provide aesthetic flexibility for design-conscious projects.

Proper installation techniques and maintenance practices determine how well these materials perform in your specific environment.

Installation and Maintenance Considerations

Foundation and Mounting Requirements

Proper installation starts with accurate floor measurements and level surfaces that prevent future alignment problems. Floor-mounted installations require concrete anchors rated for at least 250 pounds of lateral force per mounting point, while ceiling-hung systems need structural support capable of handling 300 pounds per linear foot. Pilaster shoes must sit flush against the floor with zero gaps (any looseness compromises the entire stall system and creates safety hazards). Wall brackets need backing support through drywall into structural studs or concrete, and toggle bolts in hollow walls lead to failure within six months. Professional installers complete standard three-stall installations in four to six hours, while DIY attempts often take two full days and result in alignment issues that require professional correction.

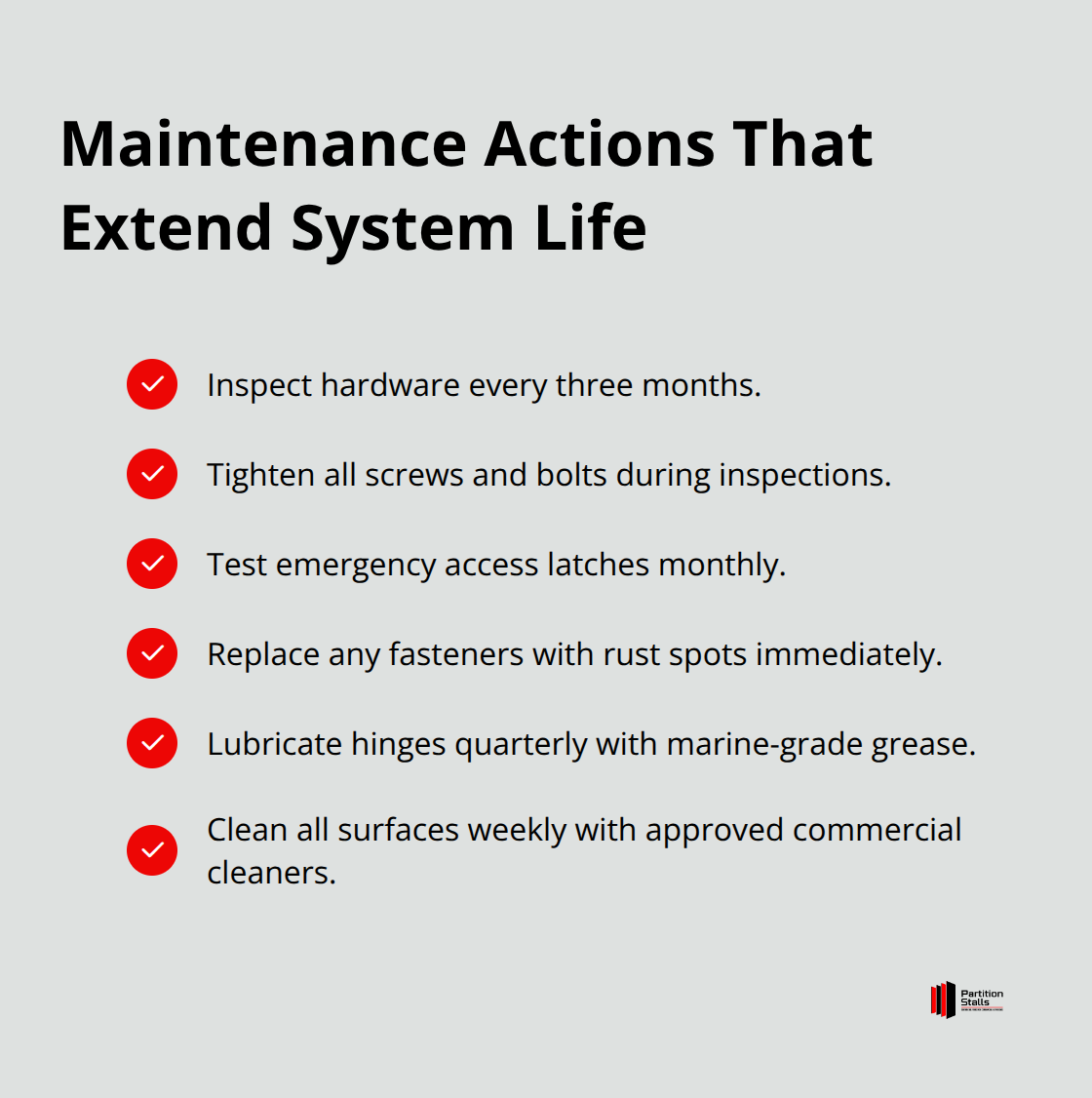

Regular Inspection Schedules

Hardware inspection every three months prevents partition failures and extends system life by five to eight years according to facility management studies. Tighten all screws and bolts during these inspections, as loose fasteners cause panel misalignment and door operation problems. Check emergency access latches monthly to verify proper function, as broken latches create privacy violations that expose facilities to liability issues.

Replace any fasteners showing rust spots immediately, as corrosion spreads rapidly in high-humidity environments and leads to structural instability.

Lubrication and Cleaning Protocols

Lubricate hinges quarterly with marine-grade grease to prevent binding and squeaking (standard household oils attract dirt and worsen performance). Stainless steel components need only basic cleaning, while laminate surfaces require gentle cleaners without ammonia or bleach that cause permanent discoloration and surface damage. Clean all surfaces weekly with approved commercial cleaners to maintain hygiene standards and prevent buildup that damages hardware components over time.

Final Thoughts

Toilet partition parts function as an integrated system where each component affects overall performance and user satisfaction. Panels provide privacy and structure, while hinges and latches handle daily operations that determine long-term reliability. Support brackets and hardware maintain stability under constant use.

Material selection drives partition longevity and maintenance costs. Stainless steel delivers 15 to 25 years of service in high-traffic facilities, while phenolic cores excel in moisture-heavy environments. Plastic laminate serves budget-conscious projects with moderate usage demands (though it requires more frequent replacement in busy facilities).

Quality installation and regular maintenance extend partition life by five to eight years. Professional installation prevents alignment issues, while quarterly inspections catch problems before they become expensive repairs. We at Partition Stalls help facility managers select appropriate toilet partition parts that match their specific needs and budget requirements.