Getting toilet partition height codes right is non-negotiable. Building inspectors won’t approve your facility without compliance, and mistakes during installation can force expensive retrofits.

At Partition Stalls, we’ve helped countless facility managers navigate these requirements without headaches. This guide walks you through the standards, the compliance process, and how to select systems that meet code from day one.

What Height Standards Actually Apply to Your Facility

The ADA and IBC Foundation

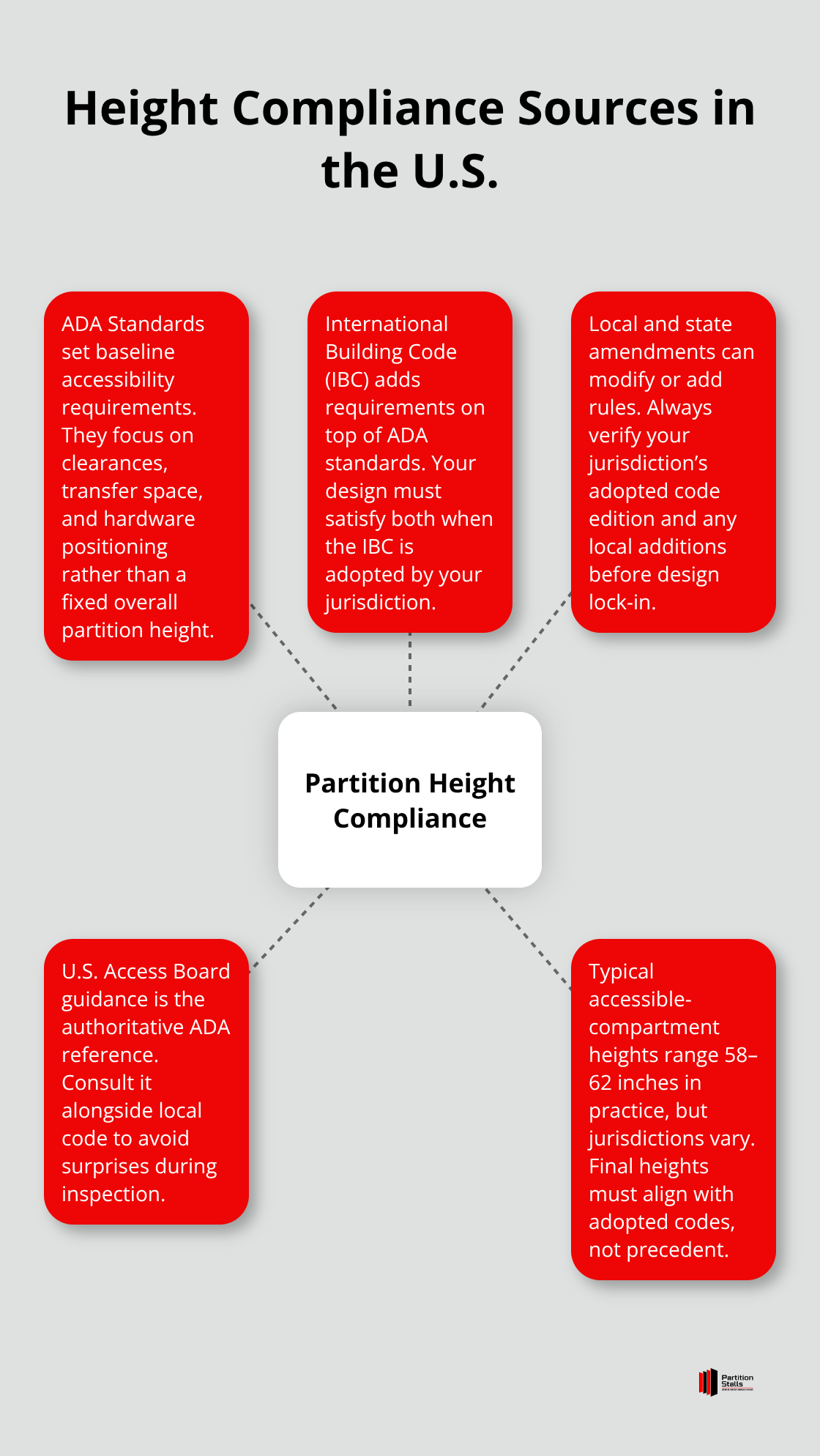

ADA Standards for Accessible Design set the baseline for toilet partition heights in the United States, but this is where confusion starts. The ADA does not mandate a specific overall partition height. Instead, it requires accessible toilet compartments to meet precise dimensions for water closet clearance, grab bar placement, and door width. The International Building Code layers additional requirements on top of ADA standards. Many states and municipalities then add their own rules, creating a patchwork that catches facility managers off guard.

The U.S. Access Board maintains the authoritative ADA Standards, and you must consult both the current ADA guidance and your local building code before finalizing any partition design. In practice, most commercial restrooms use partitions between 58 and 62 inches tall for the accessible compartment, but this varies significantly depending on your jurisdiction’s specific requirements.

Why Local Code Matters More Than Precedent

The real problem is that many facility managers rely on what they see in other buildings rather than checking their specific code. Your building inspector will not accept a partition height just because it worked elsewhere. What matters is documented compliance with your jurisdiction’s adopted code edition, typically the ADA Standards paired with a specific IBC year.

Privacy Gaps and Structural Integrity

Privacy gaps and structural integrity directly affect whether partitions pass inspection. The ADA Standards require a 60-inch diameter turning space or T-shaped maneuvering area inside the compartment, and this space cannot be obstructed by partition gaps or hardware. Front toe clearance must provide at least 9 inches above the finished floor with 6 inches of depth beyond the partition, unless the compartment is 65 inches deep or deeper for floor-mounted toilets.

Many facility managers assume taller partitions automatically mean better privacy, but code compliance depends on minimizing visible gaps at top and bottom while maintaining required clearances. Partitions must also withstand consistent use without sagging or shifting, which directly impacts height stability over time.

Material Selection and Installation

Phenolic, solid plastic, and powder-coated steel materials perform best in moisture-heavy environments because they resist warping that reduces effective height. Poor installation anchoring is the leading cause of partition failure during inspections. Your facility needs dimensioned construction drawings showing exact top-of-partition height, bottom edge clearance, and distances from fixtures before permit submission. This documentation protects you during inspections and future retrofits.

Planning for Renovation or New Construction

If you renovate an existing restroom, assess whether current partitions can be raised or replaced to meet current standards, because retrofitting after occupancy costs significantly more than getting it right initially. Understanding these compliance layers now positions you to select the right partition system and avoid costly mistakes during the approval process.

Getting the Dimensions Right on the First Try

Wheelchair and Ambulatory Compartment Specifications

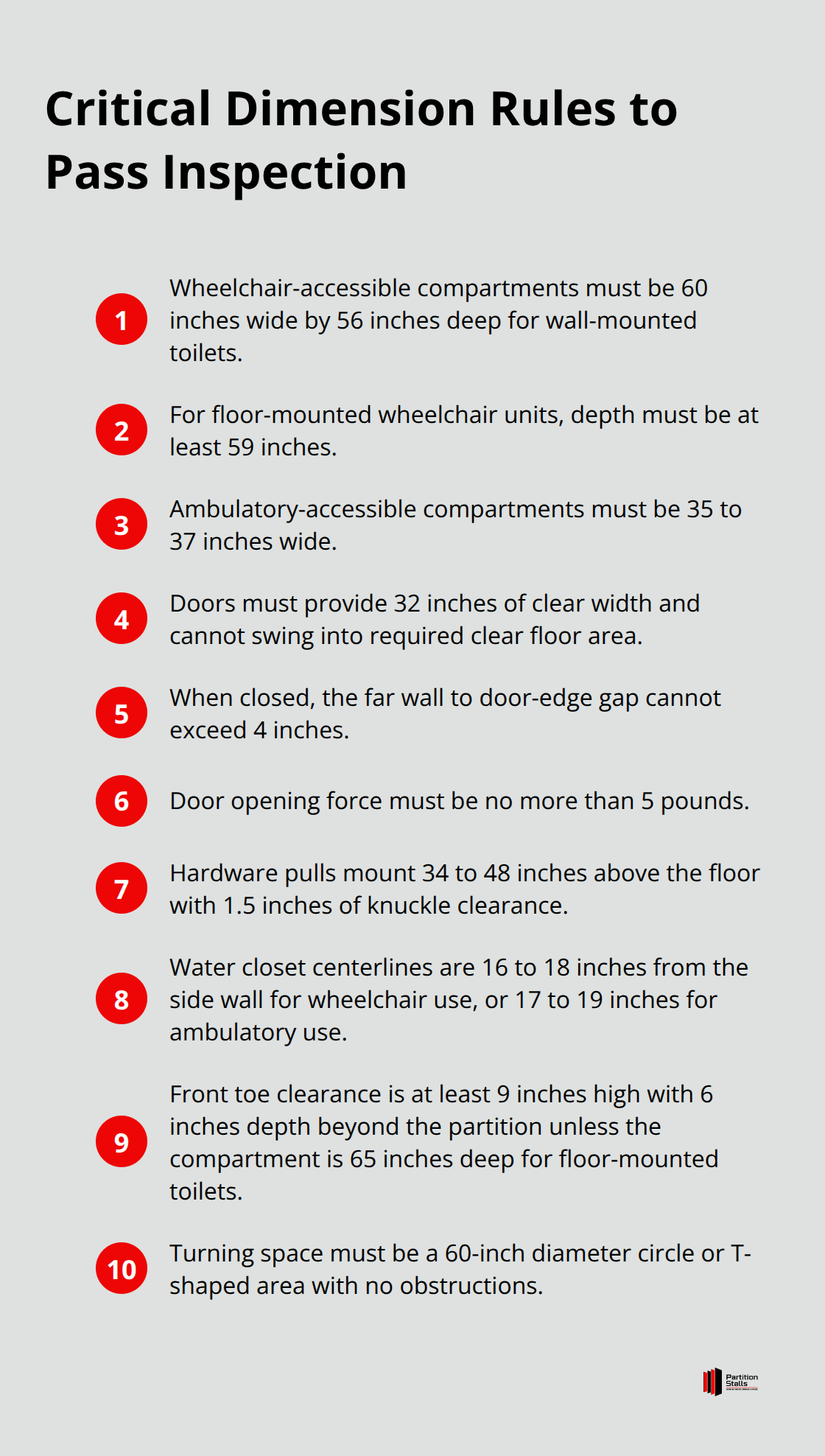

The ADA Standards require wheelchair-accessible compartments to measure exactly 60 inches wide by 56 inches deep for wall-mounted toilets, or 59 inches deep for floor-mounted units. These are minimums, not suggestions. Your building inspector will measure these spaces, and even one inch short triggers a rejection. Ambulatory-accessible compartments follow stricter width limits-between 35 and 37 inches-to provide parallel grab bars and serve users who need assistance while standing or transferring. If your facility has six or more toilets and urinals combined, you must provide at least one wheelchair compartment and one ambulatory compartment, not one or the other. Many facility managers overlook this requirement and end up replacing entire partition systems after inspection fails.

Door Placement and Hardware Requirements

The door must clear 32 inches of width, which sounds straightforward until you realize the door swing cannot intrude into the required compartment area. This means your door placement and hinge selection demand precision from the start. Partition doors swing inward or outward, but the maximum distance from the farthest side wall to the door edge cannot exceed 4 inches when the door closes. Your building inspector measures this with a straightedge, and gaps larger than 4 inches are violations. Door opening force must not exceed 5 pounds, which eliminates heavy-duty hardware that looks professional but fails accessibility testing.

Hardware pulls must mount between 34 and 48 inches from the floor with 1.5 inches of knuckle clearance.

Water Closet Positioning and Clearance Zones

Water closet centerlines must sit 16 to 18 inches from the side wall for wheelchair access, or 17 to 19 inches for ambulatory use. These distances control transfer space and grab bar positioning, so they cascade into every other dimension you specify. Front partition toe clearance requires at least 9 inches above the finished floor with 6 inches of clear depth beyond the partition itself. If your compartment depth reaches 65 inches or more for floor-mounted toilets, this requirement disappears entirely, which is why some facility managers add depth to simplify compliance. Side toe clearance vanishes completely if the stall width reaches 66 inches. The turning space inside the compartment must be 60 inches in diameter or T-shaped per ADA Standards, and nothing-not grab bars, not dispensers, not partition hardware-can obstruct this zone. This is where many installations fail inspection.

Documentation and Inspector Coordination

Arrive at your first meeting with building inspectors with dimensioned construction drawings showing exact measurements for compartment width and depth, door placement, hardware heights, grab bar locations, and clearances from all fixtures. Inspectors appreciate detailed drawings because they reduce back-and-forth revisions. Request the specific code edition your jurisdiction adopted-whether it’s the 2010 ADA Standards, 2015 IBC, or later versions-because requirements shift between editions. Ask inspectors directly whether your state or municipality adds requirements beyond federal ADA standards, as many do. Some jurisdictions mandate vertical grab bars in addition to horizontal ones, which the ADA does not require but the International Building Code may reference. Document the inspector’s verbal guidance in writing and follow up with email confirmations. This creates a paper trail protecting you if disputes arise later during occupancy. With these dimensions locked in and inspector approval secured, material selection becomes your next critical decision-and the wrong choice can undermine months of planning.

Choosing Materials That Survive Code Inspections

Material Selection for Long-Term Compliance

Phenolic, solid plastic, and powder-coated steel stand as the only materials worth considering for commercial restrooms because they resist moisture damage that destroys partition integrity over time. Phenolic performs best in high-moisture environments like gyms and pools because it does not absorb water, warp, or lose structural height as humidity fluctuates. Solid plastic (high-density polyethylene) costs less than phenolic but still withstands daily cleaning chemicals and moisture without degradation. Powder-coated steel offers affordability and durability in standard office settings, though it requires vigilant inspection for rust at anchor points where moisture accumulates.

Cheap alternatives like laminate or MDF fail in restroom conditions and trigger code violations when inspectors measure partition height and find sagging or swelling. Material choice directly determines whether partition height remains stable through inspections conducted five, ten, or fifteen years after installation.

Hardware and Anchoring Systems

Vandal-resistant hardware and secure anchoring prevent the height loss that causes most post-installation failures. Partition doors need heavy-duty hinges rated for commercial use, not residential-grade hardware that loosens after thousands of cycles. Floor and wall anchors must account for the moisture and vibration that loosen fasteners over time, so stainless steel or coated hardware resists corrosion better than standard steel.

Install partitions with dimensioned construction drawings that specify anchor depth, fastener type, and spacing intervals, then photograph the installation before walls close and fixtures get added. Request your installer provide a signed declaration confirming dimensions match approved drawings, because this documentation protects you during future inspections and retrofits.

Maintenance and Inspection Protocols

High-traffic environments like restaurants and gyms demand annual inspections to verify partition height and hardware tightness before drift accumulates. These inspections catch loosening fasteners and material degradation before they trigger code violations. Taller partitions measuring 62 inches or more cost more upfront but eliminate toe-clearance requirements in some jurisdictions, simplifying both compliance and long-term maintenance.

The difference between a partition system that passes inspection every time and one that requires costly fixes comes down to material selection and installation rigor, not luck.

Final Thoughts

Toilet partition height code compliance protects your facility from violations that cost $55,000 to $75,000 for first offenses and up to $150,000 for subsequent breaches. Wheelchair users depend on precise clearances to transfer safely, ambulatory users require grab bars at exact heights, and inspectors measure every dimension with tools that accept no approximations. Start by identifying your jurisdiction’s adopted code edition and consulting directly with your building inspector about any local additions to ADA Standards.

Material selection determines whether partitions maintain structural integrity through years of moisture exposure and daily use. Phenolic and solid plastic resist warping that destroys height compliance, while poor anchoring causes most post-installation failures. Install with dimensioned construction drawings, photograph the work, and request signed declarations from your installer confirming dimensions match approved plans.

Accessible restrooms signal that your facility respects all visitors and builds reputation while reducing liability exposure. Contact Partition Stalls for a free consultation to transform your restroom with solutions that meet toilet partition height code requirements and exceed expectations.