Selecting the right toilet partition manufacturer impacts your commercial restroom project’s success, budget, and long-term maintenance costs.

Poor manufacturer choices lead to installation delays, subpar materials, and costly repairs that drain facility budgets. We at Partition Stalls have seen countless projects fail due to inadequate research and rushed decisions.

This guide reveals the key factors that separate reliable manufacturers from problematic ones.

What Makes a Manufacturer Worth Your Investment

Material Standards That Actually Matter

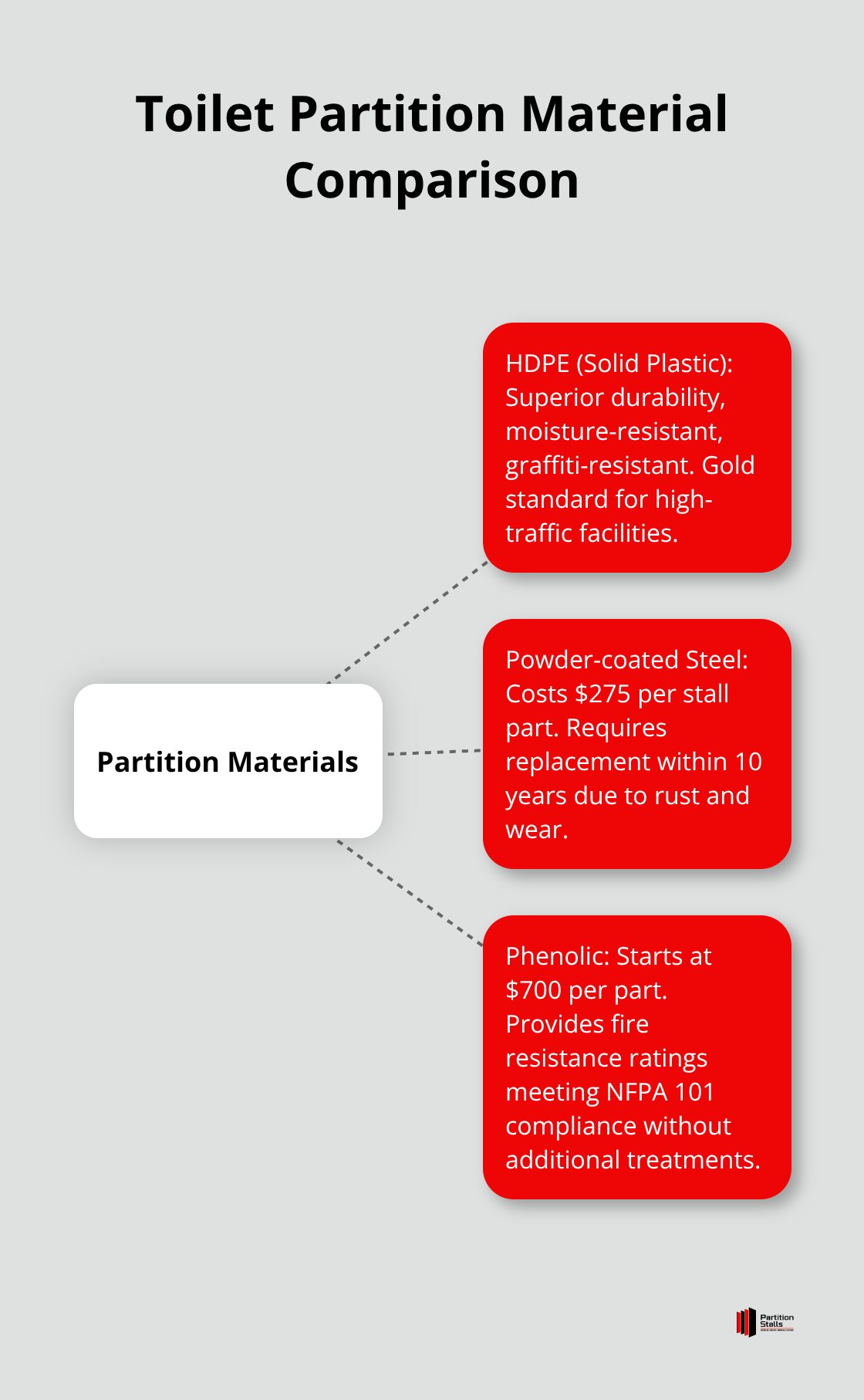

Solid plastic HDPE partitions deliver superior durability and withstand moisture better than any alternative, making them the gold standard for high-traffic facilities. Powder-coated steel costs around $275 per stall part but requires replacement within 10 years due to rust and wear. Phenolic partitions start at $700 per part yet provide fire resistance ratings that meet NFPA 101 compliance requirements without additional treatments. Scranton Products reports their HDPE materials resist graffiti and scratches that destroy laminate options within months of installation.

Design Flexibility That Fits Your Space

Manufacturers that offer fewer than 15 color options limit your design potential and force compromises that affect user experience. Compact laminate provides over 30 color choices while it maintains durability standards that plastic laminate cannot match in moisture-heavy environments. Custom size capabilities separate professional manufacturers from budget suppliers who stock only standard dimensions. ASI Global Partitions leads with their Ultimate Privacy option that features taller doors and minimal gaps (addressing modern privacy toilet partitions expectations).

Installation Support That Prevents Project Delays

Hadrian maintains a 99% on-time shipment rate that keeps projects on schedule, while manufacturers with poor logistics cause costly construction delays. Professional installation courses reduce labor costs by 15-20% compared to contractors who learn partition systems on-site. Technical support during installation prevents the measurement errors and hardware failures that plague 30% of commercial restroom projects. Manufacturers who provide detailed installation manuals and phone support minimize the callbacks that add $200-500 per stall to project costs.

Quality Certifications That Matter

Top manufacturers maintain ADA compliance documentation and LEED requirements that modern facilities demand. Fire safety certifications separate professional suppliers from budget alternatives that fail building inspections. Environmental certifications like EPD and Greenguard validate sustainability claims that architects require for green building projects.

The next step involves comparing specific manufacturers to identify which companies deliver on these standards consistently.

Which Manufacturers Actually Deliver on Quality

Bobrick stands as the industry heavyweight with over 100 years of experience and offers solid color reinforced composite partitions with a 25-year warranty that surpasses most competitors. Their SCRC material costs approximately $700 per stall part but eliminates the rust issues that plague powder-coated alternatives within 5-7 years. Scranton Products specializes exclusively in HDPE solid plastic partitions that resist vandalism in schools and high-traffic facilities, with color embedded throughout the material to prevent the surface damage that destroys laminate options. Bradley Mills provides powder-coated steel partitions at $275 per stall part with installations at O’Hare International Airport and National Aquarium in Baltimore that prove their reliability in demanding environments.

Construction Standards That Separate Leaders from Budget Options

Hadrian pioneered powder-coated toilet partitions with fire-resistant properties that meet codes without additional treatments and maintains their 98% damage-free shipment rate through multiple distribution centers. ASI Global Partitions focuses on privacy with their Ultimate Privacy system that features minimal gaps and taller doors to address modern restroom expectations. Metpar offers competitive prices with fast delivery from multiple U.S. distribution centers, which reduces delivery costs by 20-30% compared to single-location manufacturers.

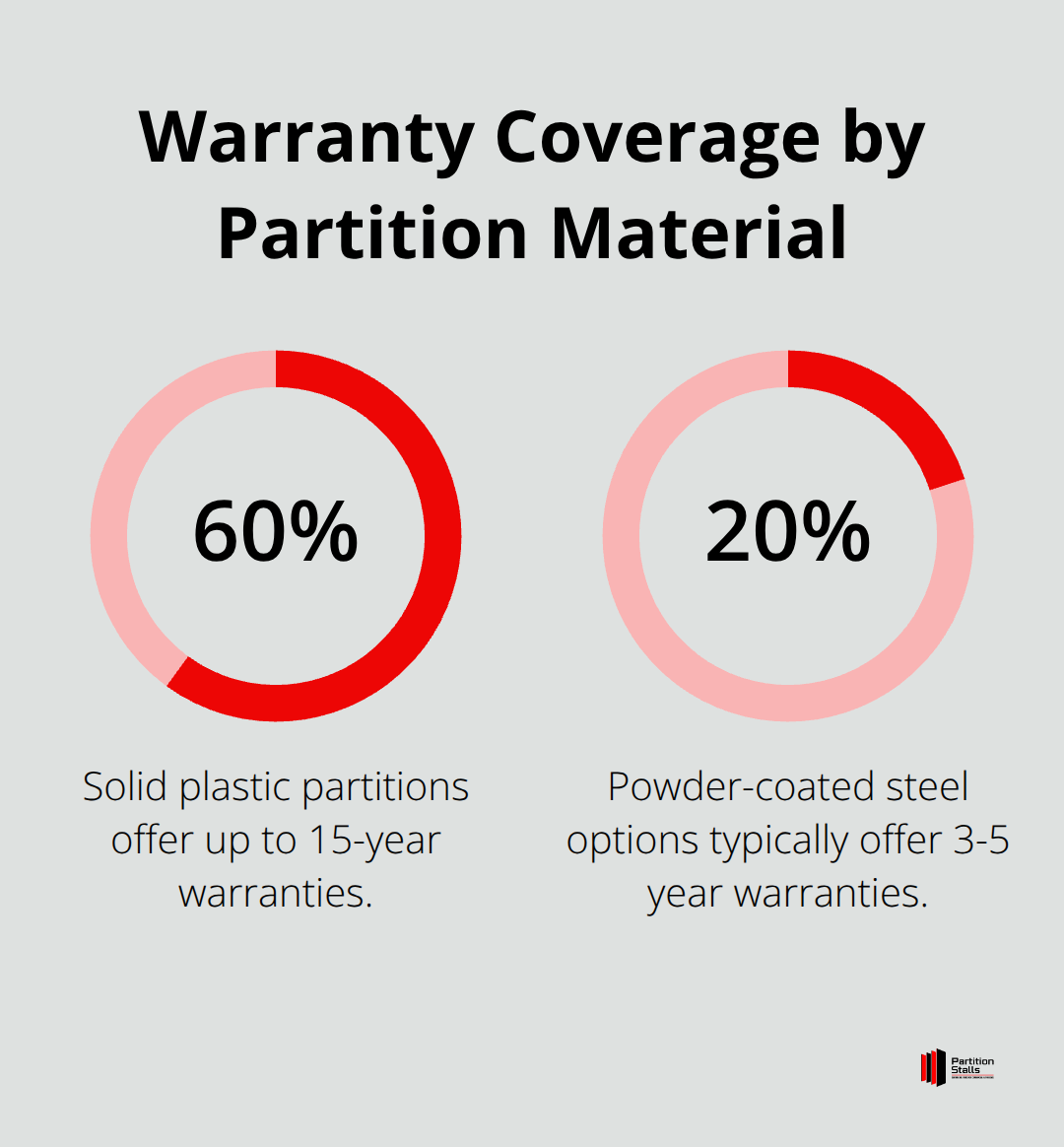

Warranty Coverage That Protects Your Investment

Solid plastic partitions from top manufacturers include 15-year warranties while powder-coated steel options typically offer 3-5 years maximum coverage. Phenolic partitions command premium prices at $700+ per part but deliver warranties up to 25 years with maintenance requirements 60% lower than metal alternatives. Manufacturers who provide comprehensive technical support reduce callback costs that average $200-500 per stall across the industry.

Material Performance in Real-World Conditions

HDPE partitions outperform metal and laminate in conditions such as schools and gyms where hygiene remains essential (with moisture resistance that prevents the warping common in other materials). Compact laminate maintains over 30 color options while it delivers durability standards that plastic laminate cannot match in moisture-heavy environments. Stainless steel partitions combine recycled content with vandal resistance, though they require careful maintenance in high-moisture areas.

However, even quality manufacturers can present red flags that signal potential problems with your project timeline and budget.

Red Flags to Avoid When Choosing a Manufacturer

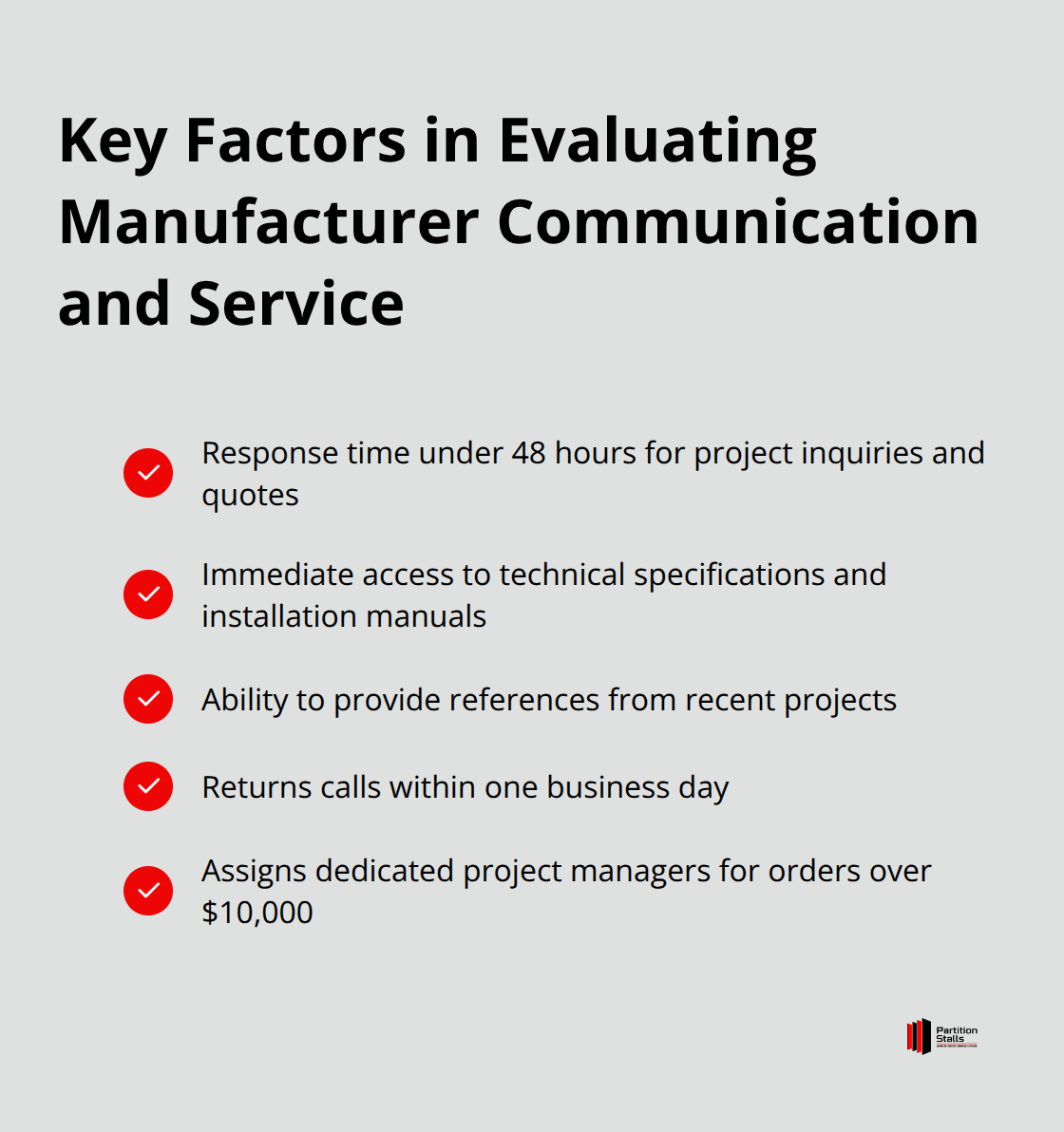

Manufacturers who take longer than 48 hours to respond to project inquiries or provide quotes signal organizational problems that will plague your entire project timeline. Companies that cannot provide immediate access to technical specifications or installation manuals lack the documentation systems needed for commercial projects. Metpar’s multiple distribution centers enable faster response times compared to single-location manufacturers who struggle with customer service during peak seasons.

Poor Communication and Unresponsive Service

Manufacturers who refuse to provide references from recent projects or dodge questions about warranty claims typically hide poor performance records that surface during critical project phases. Companies that fail to return calls within one business day demonstrate the same negligence they will show during installation crises. Suppliers who cannot assign dedicated project managers to orders over $10,000 lack the organizational structure needed for commercial installations.

Outdated Material Technology and Limited Options

Suppliers who offer fewer than 10 color choices in their primary material lines cannot accommodate modern design requirements that architects demand for commercial spaces. Manufacturers still promote plastic laminate despite durability concerns from prolonged exposure to sharp objects or harsh solvents that require replacement within 2-3 years. Companies without HDPE solid plastic options miss the material that delivers 15-year warranties and requires 60% less maintenance than powder-coated alternatives.

Inadequate Installation Support and Training

Suppliers without certified installation programs leave contractors to learn complex partition systems through trial and error (which adds $200-500 per stall to project costs through callbacks and corrections). Manufacturers who ship products without detailed hardware instructions or technical support phone lines create installation delays that extend project timelines by 2-4 weeks. Companies that cannot provide on-site installation oversight for projects over 50 stalls lack the expertise needed for large commercial installations.

Missing Certifications and Compliance Documentation

Manufacturers who cannot provide fire safety certifications like ASTM E84 create code violations that halt project approvals and force costly material changes. Companies without ADA compliance documentation expose projects to legal risks that cost thousands in retrofitting expenses. Suppliers who lack environmental certifications like Greenguard or EPD cannot support LEED projects that modern facilities require.

Final Thoughts

The right toilet partition manufacturer determines whether your commercial restroom project succeeds or becomes a costly maintenance burden. Quality materials like HDPE solid plastic with 15-year warranties cost more upfront but eliminate the replacement cycles that plague cheaper alternatives within 5-7 years. Price-focused decisions create false savings when powder-coated steel partitions require replacement at $275 per stall while phenolic options deliver 25-year performance despite higher initial costs.

Manufacturers with poor communication, limited material options, or missing certifications signal problems that surface during critical installation phases. Request material samples, warranty documentation, and installation support details from potential suppliers before you commit to any project. Verify fire safety certifications and ADA compliance to avoid delays that affect your entire facility timeline (and budget constraints that emerge from code violations).

We at Partition Stalls provide comprehensive commercial restroom solutions with expert guidance through material selection, customization options, and installation support. Our team helps you transform your restroom facilities with durable, stylish solutions that meet your specific requirements. Contact us for a free consultation to discuss your project needs and explore the best options for your facility.