Overhead braced toilet partitions offer superior stability and space efficiency compared to other mounting systems. These partitions attach to ceiling structures, eliminating floor obstructions while providing excellent structural support.

We at Partition Stalls see many facilities struggle with partition selection due to complex requirements and material options. The right choice depends on traffic volume, budget constraints, and long-term maintenance needs.

What Makes Overhead Braced Partitions Stand Out

Superior Structural Performance

Overhead braced partitions deliver exceptional stability through their aluminum headrail system, which distributes weight across ceiling anchors rather than floor mounts alone. This design provides excellent impact resistance, making these partitions ideal for high-traffic facilities like schools and airports. The 82-inch height standard provides 12 inches of clearance above doors, which significantly reduces vandalism attempts while it maintains user privacy. Installation costs average $85 to $125 per stall, with experienced contractors who complete each unit in 30-45 minutes due to the straightforward mount process.

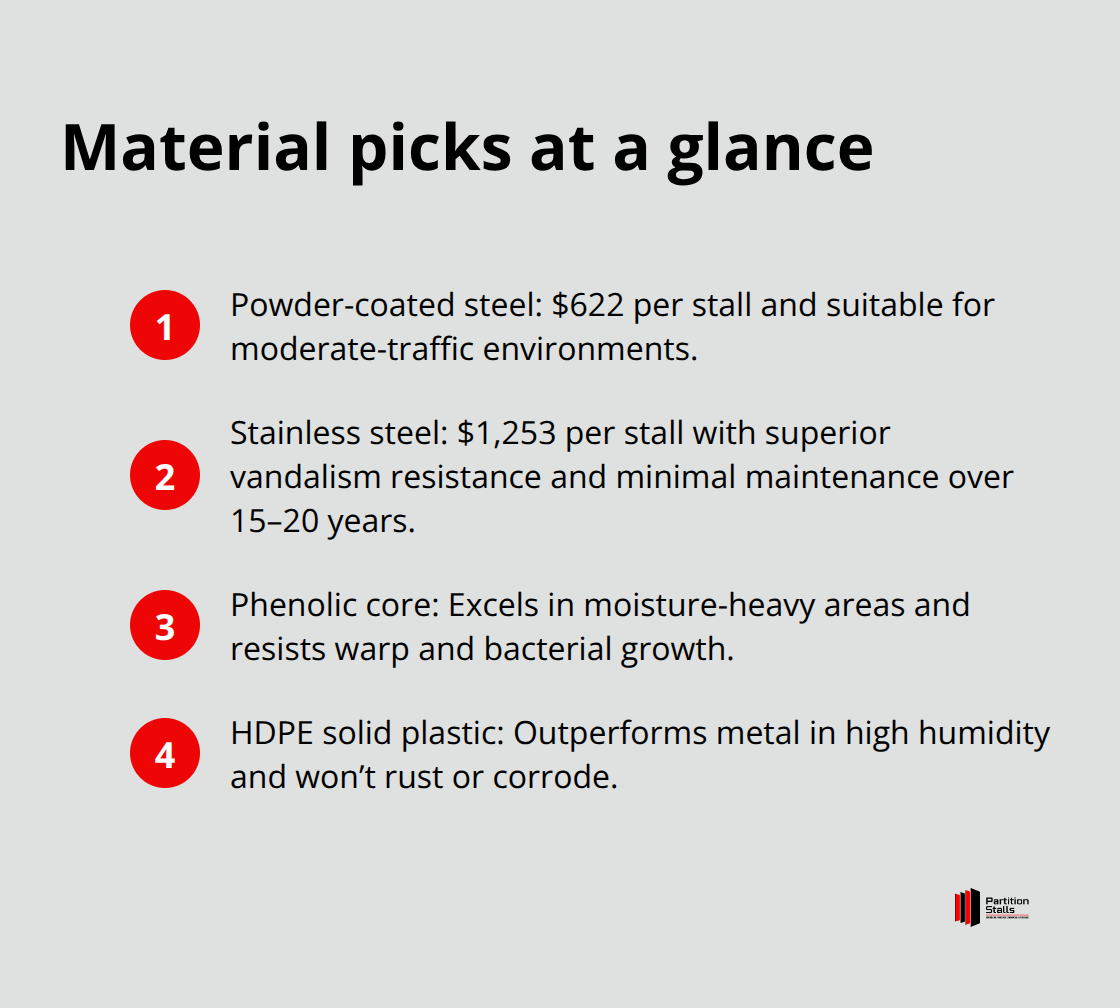

Material Selection Drives Long-Term Value

Powder-coated steel remains the most economical choice at $622 per stall and offers infinite color options with solid corrosion resistance for moderate-traffic environments. Stainless steel partitions cost $1,253 per stall but provide superior vandalism resistance and require minimal maintenance over 15-20 years. Phenolic core materials excel in moisture-heavy environments like pools and gyms, with full water contact resistance that prevents warp and bacterial growth.

HDPE solid plastic partitions outperform metal options in high-humidity areas and maintain structural integrity without rust or corrosion issues that plague traditional materials.

Installation and Space Benefits

Overhead braced systems eliminate floor-level obstructions and allow complete floor access while they maintain structural strength comparable to floor-to-ceiling installations. These partitions work effectively with ceiling heights from 8 to 12 feet and require standard structural support without specialized construction modifications. The headrail design deters climb attempts and vandalism through its uncomfortable grip surface, which reduces maintenance requirements compared to floor-mounted alternatives in institutional areas.

Traffic Volume Considerations

High-traffic facilities benefit most from overhead braced systems because the design handles constant use without structural compromise. Schools report fewer maintenance calls when they choose overhead braced partitions over floor-mounted alternatives. The aluminum headrail distributes stress across multiple anchor points, which prevents the wobble and looseness that develops in floor-only systems after heavy use. These factors become even more important when you evaluate your facility’s specific needs and user patterns.

What Factors Drive Your Partition Selection Decision

Facility Type Determines Material Requirements

Educational facilities require vandalism-resistant materials like stainless steel or phenolic core, which withstand daily abuse from heavy student traffic. Healthcare environments demand non-porous surfaces that resist bacteria growth, making HDPE or phenolic materials the only viable options due to infection control standards. Restaurant facilities need moisture-resistant partitions because kitchen humidity and frequent cleaning create corrosive conditions that destroy powder-coated steel within 3-5 years.

Office buildings with controlled access can use economical powder-coated steel since traffic remains light and vandalism stays minimal. Gyms and pools require full water-contact materials like phenolic core because standard materials fail when exposed to chlorine and constant moisture.

Budget Analysis Beyond Initial Purchase Price

Installation costs vary dramatically based on ceiling access and structural requirements, with modular systems offering faster installation times and reduced on-site labor costs. Powder-coated steel saves money initially but replacement costs every 8-10 years make total ownership expensive compared to stainless steel that lasts 20+ years.

Phenolic partitions cost $200-300 more per stall than powder-coated options but eliminate replacement needs in high-moisture environments (saving thousands in long-term expenses). Maintenance expenses differ significantly between materials, with HDPE requiring zero rust treatment while powder-coated steel needs refinishing every 5-7 years at $150 per stall.

Long-Term Cost Calculations

Smart facility managers calculate 15-year total costs rather than focus on purchase price alone because material performance directly impacts operational budgets and user satisfaction over time. Stainless steel partitions that cost $1,253 per stall often prove more economical than $622 powder-coated alternatives when you factor in replacement cycles and maintenance requirements.

High-traffic facilities see the greatest return on investment from premium materials (particularly in schools and healthcare settings where durability prevents costly downtime). These financial considerations become even more important when you evaluate common selection mistakes that can derail your project budget and timeline.

What Selection Mistakes Cost You Most

ADA Compliance Failures Create Legal Liability

The Americans with Disabilities Act requires wheelchair accessible compartments in all multi-user restrooms, with specific clearance measurements that overhead braced partitions must accommodate. Standard compartments need 60-inch minimum width and 59-inch depth, while ambulatory accessible stalls require 35-36 inch door width when six or more compartments exist. Local building codes often exceed federal ADA requirements, with California mandating 32-inch minimum door openings and Texas requiring specific grab bar positions that affect partition placement.

Facilities face significant fines when they install non-compliant partitions, plus costly retrofit expenses that double original installation costs. The ADA guidelines set accessibility standards for places of public accommodation and commercial facilities, which directly impacts partition layout and material selection decisions.

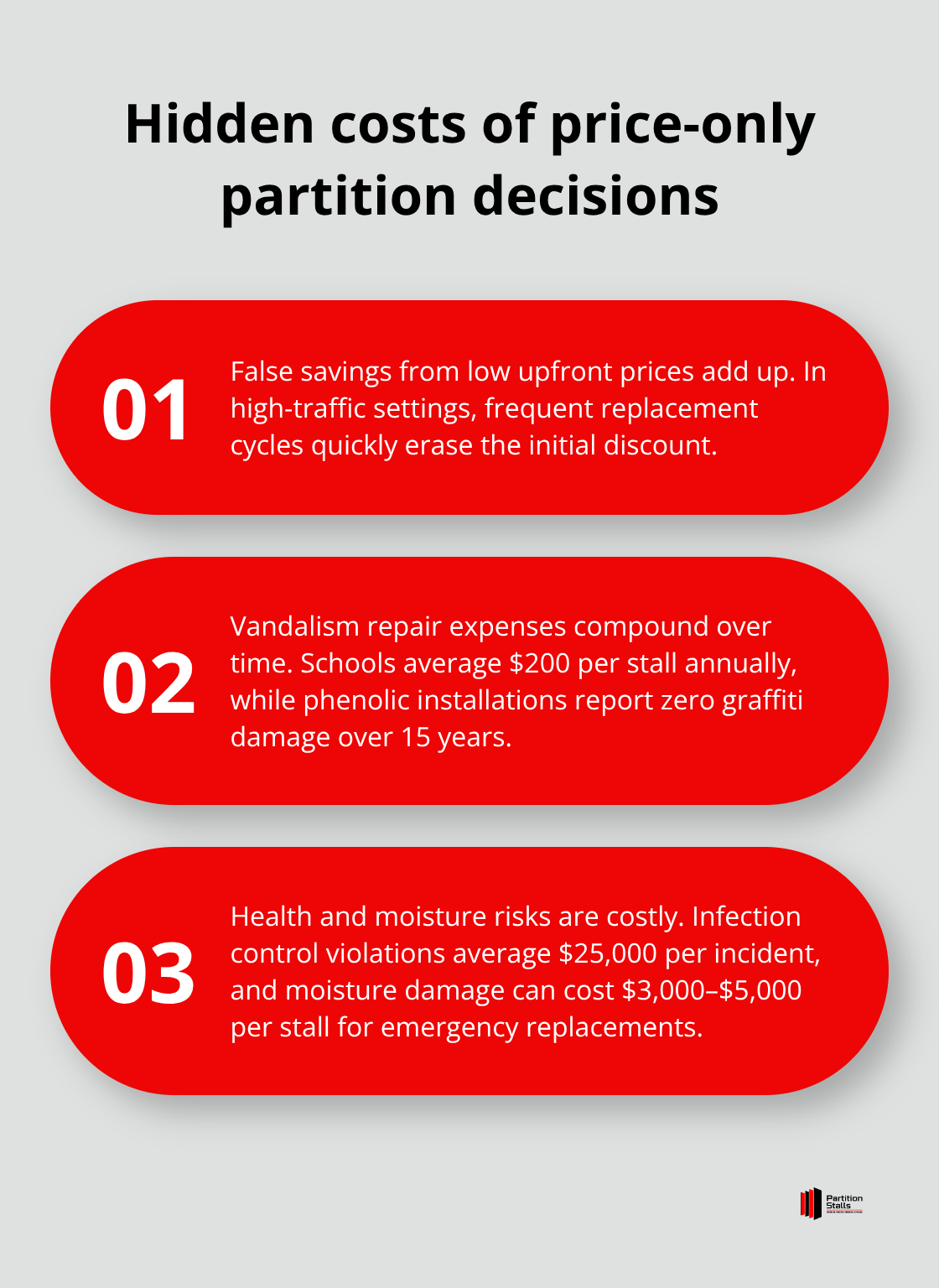

Price-Only Decisions Generate Hidden Costs

Facilities that choose powder-coated steel at $622 per stall over stainless steel at $1,253 create false savings when replacement cycles begin after 8-10 years in high-traffic environments. Schools that select cheap materials typically spend $200 per stall annually on vandalism repairs, while facilities with phenolic partitions report zero graffiti damage over 15-year periods.

Healthcare facilities face infection control violations that average $25,000 per incident when partitions harbor bacteria growth from non-approved materials. Moisture damage from inadequate materials costs restaurants $3,000-5,000 per stall in emergency replacements when standard partitions fail within 3-5 years (particularly in high-humidity kitchen environments).

Expansion Plans Prevent Future Headaches

Fixed partition installations create expensive modification challenges when facilities expand or reconfigure restroom layouts, with removal and reinstallation costs that exceed new partition prices by 40%. Modular overhead braced systems allow relocation without structural damage and save $500-800 per stall during renovations compared to permanent installations that require complete replacement.

Retail and office environments need partition systems that accommodate layout changes without major construction, particularly where space optimization drives profitability and user satisfaction over time.

Final Thoughts

Smart facility managers balance material durability, traffic demands, and long-term costs when they select the right overhead braced toilet partition. Stainless steel and phenolic materials provide superior value in high-traffic environments despite higher upfront costs, while powder-coated steel serves controlled-access facilities with moderate use effectively. ADA compliance and local codes must drive your selection process to avoid costly retrofits and legal complications.

Professional consultation becomes essential when you evaluate complex requirements like moisture resistance, vandalism protection, and future expansion needs that impact total ownership costs over 15-20 years. Facilities that start with proper assessment of traffic volume, environmental conditions, and budget constraints make better material choices. The wrong partition selection creates hidden expenses that exceed initial savings by thousands of dollars (particularly in schools and healthcare facilities where durability prevents costly downtime).

We at Partition Stalls recommend thorough facility assessment before material selection to match your specific requirements with optimal performance solutions. Partition Stalls provides expert guidance and customized solutions for offices, gyms, restaurants, and public facilities. Contact our team to receive professional recommendations that balance performance, durability, and cost-effectiveness for your restroom project.