Picking the wrong toilet partition supplier can cost you thousands in repairs, replacements, and downtime. We at Partition Stalls know that most facility managers struggle to separate quality providers from those cutting corners on materials and installation.

This guide walks you through the exact criteria that matter-from durability standards to warranty coverage to proven commercial experience. You’ll learn what mistakes to avoid and how to spot a partner who actually delivers.

Key Factors to Evaluate in a Toilet Partition Supplier

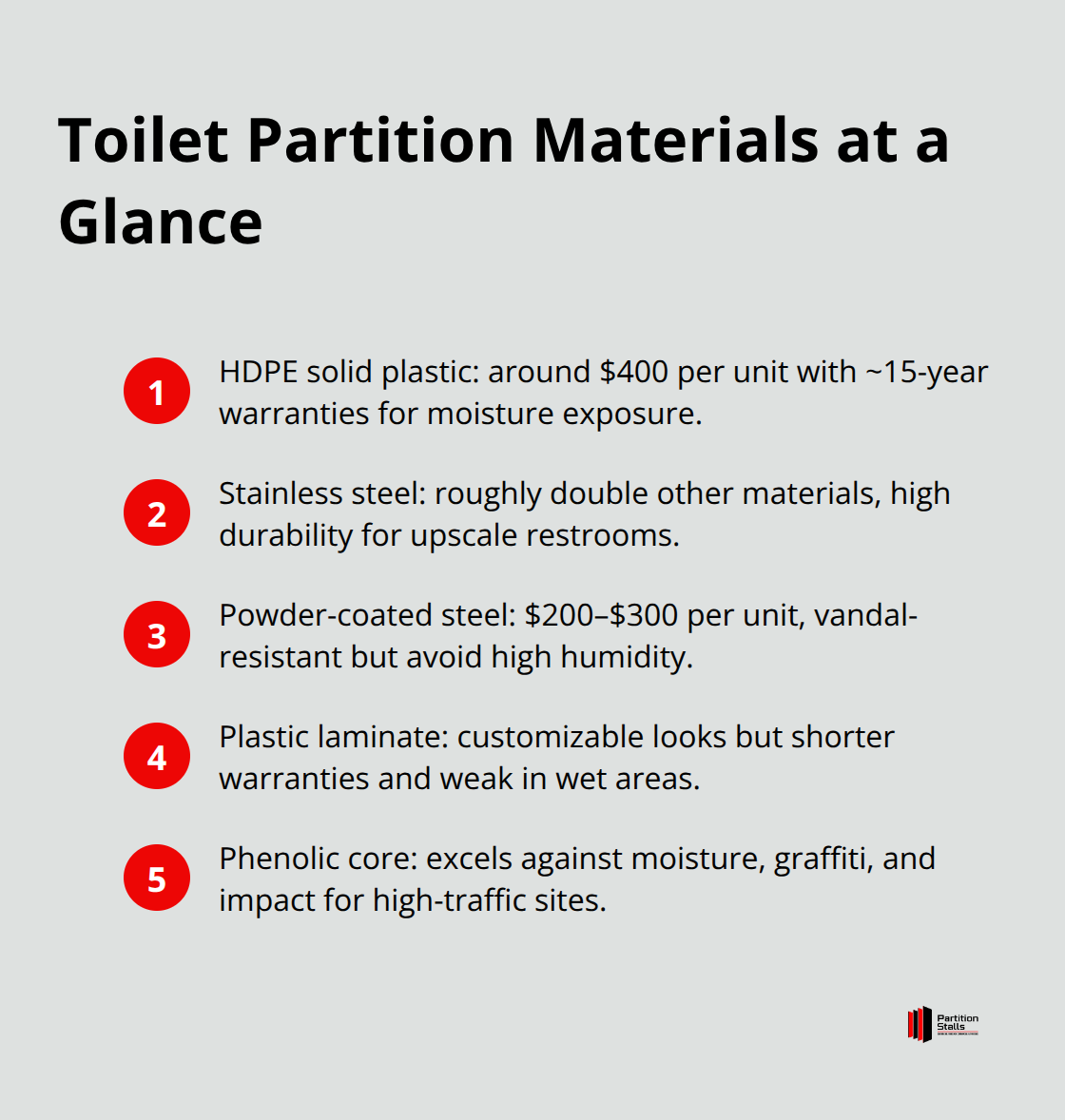

Material quality separates suppliers who cut corners from those engineering for real-world conditions. Phenolic core partitions resist moisture, graffiti, and impact far better than standard laminates-they’re the choice for high-traffic facilities like stadiums and theme parks where replacement costs add up fast. Solid plastic (HDPE) partitions start around $400 per unit depending on size and quantity, carry warranties around 15 years, and handle mold and rust that destroy cheaper alternatives. Stainless steel costs roughly twice as much as other materials but delivers unrivaled durability and resists scratches and corrosion in upscale restrooms. The real question isn’t which material is cheapest upfront; it’s which one won’t force you to renovate again in five years. Ask potential suppliers for their warranty terms-typical coverage ranges from 10 to 25 years, with solid plastic often around 15 years. Request samples and inspect them yourself rather than trusting product photos.

Powder-coated steel at $200–$300 per unit offers affordability and vandalism resistance, but performance declines in areas with excessive water exposure, making it unsuitable for pools or humid gyms. Plastic laminate provides customization with broad color and pattern options, but shorter warranties and poor performance in wet environments mean it’s a gamble for moisture-prone spaces.

Design Flexibility Without Compromise

A supplier worth partnering with handles non-standard dimensions, unusual wall conditions, and custom finishes without treating your project like an exception. Panel widths range from 10 inches to 78 inches across all materials, so stall configurations should fit your restroom layout, not force you to accept standard sizes that waste space. Lead times vary significantly-powder-coated metal and stainless steel typically take 3–5 days, while plastic laminate requires 7–10 days and solid phenolic 5–10 days depending on the core type. If your project timeline is tight, the wrong supplier can delay opening by weeks. Verify whether the supplier offers field measurement services and design assistance; this prevents costly installation errors and ensures ADA compliance from the start. Customization capabilities matter most when you’re matching existing architecture or branding requirements. Stainless panels come with leather grain or diamond texture finishes, while phenolic options offer rich finishes. Ask whether the supplier provides color charts before purchase and whether pattern orientation is managed correctly for wider panels (those over 60 inches have specific pattern direction rules).

Support That Extends Beyond Delivery

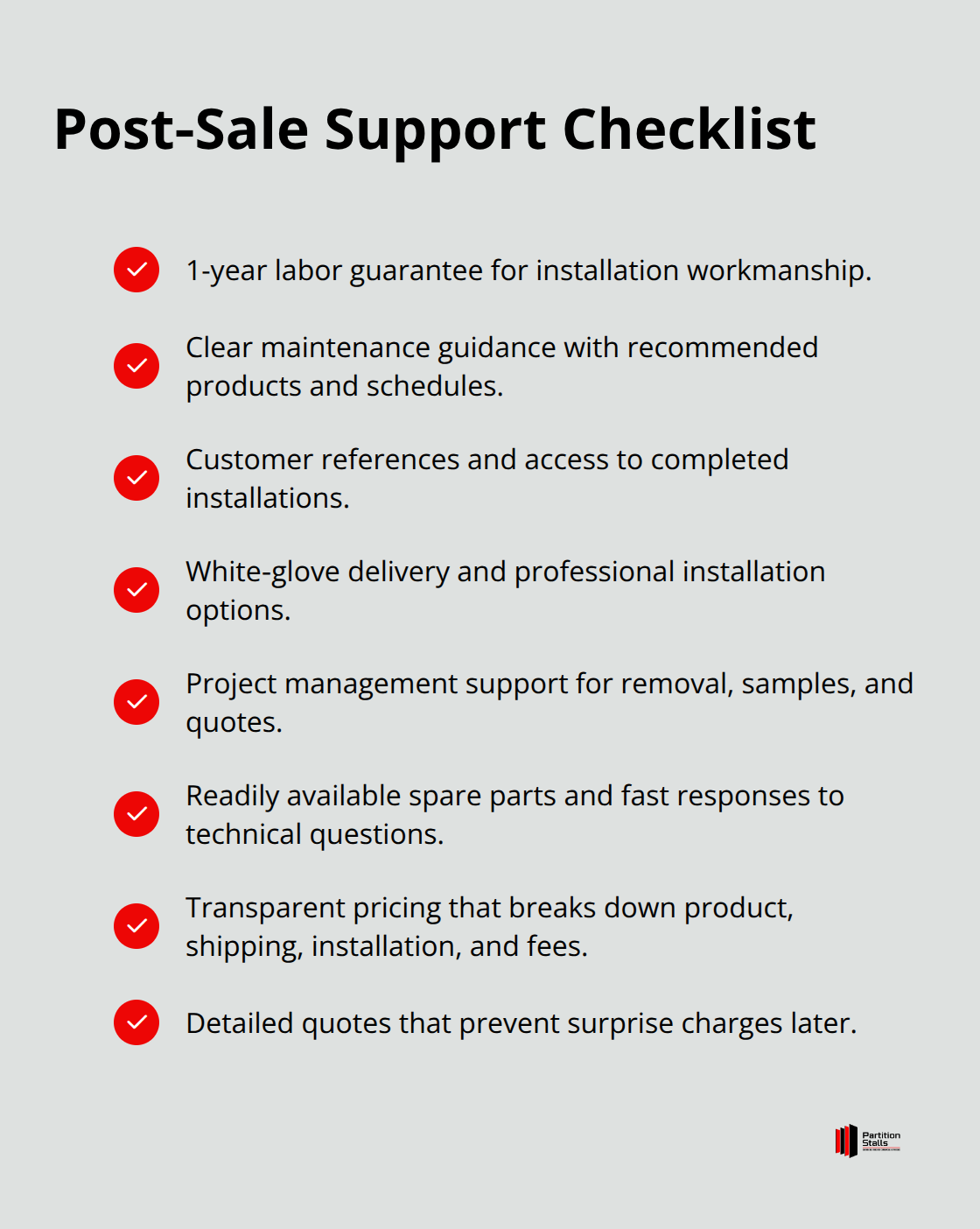

Post-sale support determines whether a supplier relationship lasts or becomes a headache. Confirm that installation includes a 1-year labor guarantee and that the supplier provides clear maintenance guidance with recommended cleaning products and schedules. Request customer references and inspect completed installations if possible-speak directly with previous clients about responsiveness and whether the supplier resolved issues quickly. White-glove delivery and professional installation options ensure on-time, clean project completion rather than leaving you to coordinate contractors. A supplier offering project management support handles compartment removal, sample provision, and quote preparation, reducing your administrative burden. Ask whether spare parts are readily available and how quickly the supplier responds to technical questions or warranty claims.

Transparent pricing that breaks down product cost, shipping, installation, and extra fees prevents surprise bills later. Suppliers who refuse detailed quotes or obscure their pricing structure often hide poor quality or unexpected charges.

What Separates Quality from Shortcuts

The materials you select determine how long your restroom investment actually lasts. High-traffic environments demand materials that withstand constant use without degrading-phenolic and stainless steel deliver this performance, while budget options like laminate fail faster in demanding conditions. A supplier who stocks multiple material options and explains the trade-offs between cost and longevity helps you make decisions based on your facility’s actual needs, not just the lowest price. Inspect how the supplier handles edge cases: Can they work with your existing wall conditions? Do they offer solutions for ADA compliance without compromising design? These answers reveal whether you’re working with a true partner or just a vendor filling orders. The next section covers the mistakes that facility managers make most often when selecting suppliers-and how to avoid them entirely.

Common Mistakes When Selecting a Partition Supplier

The True Cost of Choosing Wrong

Facility managers often assume that the cheapest bid represents the best value. A supplier quoting $250 per partition unit instead of $400 sounds like smart budgeting until that laminate partition delaminates in three years or the powder-coated steel rusts through in a humid environment. Facilities that prioritize lowest upfront price typically end up purchasing again sooner-a $15,000 replacement bill for partitions that lasted only four years versus a $6,000 investment in phenolic core partitions that deliver 15+ years of performance tells the real story. High-traffic facilities like schools and stadiums face even steeper consequences. When partitions fail in a busy restroom, you face emergency closure, facility downtime, and replacement costs that dwarf the original savings.

Phenolic partitions resist moisture, graffiti, and impact in ways that laminate simply cannot match, yet many facility managers never request samples or compare warranty terms side by side. Stainless steel costs roughly double the price of powder-coated metal, but in upscale hotels or corporate offices where restroom quality signals brand standards, the cheaper option looks shabby within months. The decision to cut corners on materials almost always costs more in the long run.

Installation and Maintenance Determine Real Project Cost

A partition supplier who quotes a price without discussing installation requirements already cuts corners. Many facility managers discover too late that their chosen supplier doesn’t offer professional installation, leaving them to hire separate contractors who may not understand partition-specific requirements. Misaligned doors, improper hardware mounting, and ADA compliance failures result from this disconnect.

Installation labor typically represents 20–30% of total project cost, yet suppliers who obscure this figure often provide minimal guidance on site preparation, wall conditions, or floor considerations. Maintenance requirements vary dramatically by material: solid plastic and phenolic partitions demand basic cleaning with standard products, while powder-coated steel requires specific rust prevention protocols in humid spaces, and laminate needs careful handling to prevent water penetration at seams. A supplier who provides detailed maintenance guidance and recommended cleaning schedules upfront prevents costly damage from incorrect care.

Request whether the supplier includes a 1-year labor guarantee and whether they provide ongoing technical support when maintenance questions arise. Facilities in high-humidity environments like pools or gyms that select laminate partitions without understanding their moisture limitations face mold, swelling, and premature failure-problems that phenolic or HDPE alternatives (which carry 15-year warranties specifically for moisture exposure) would have prevented entirely.

Compliance Gaps Create Liability and Project Delays

Building codes and ADA requirements vary by location, yet many facility managers assume their supplier will handle compliance automatically. A partition supplier who fails to verify local fire codes, accessibility standards, or height requirements can leave you with an installation that doesn’t meet regulations, forcing costly modifications or complete replacement. ADA guidelines specify door width clearances, stall dimensions, grab bar placement, and turning radiuses; suppliers without Division 10 expertise often miss these details during the design phase.

Verify that your supplier can provide compliance documentation and certifications before purchase, not after installation crews arrive. Some jurisdictions require fire-rated partitions in certain facility types, and choosing a supplier unfamiliar with these requirements means discovering the problem during final inspection. Request that the supplier conduct field measurements and design your restroom layout with code compliance built in from the start. Transparent suppliers outline compliance requirements upfront and explain how their material and design choices meet local standards; those who brush past these questions typically lack the expertise to navigate them.

The next section reveals what separates reliable suppliers from those who disappear after the invoice is paid-and how to spot a partner who actually stands behind their work.

What to Look for in a Reliable Partnership

A supplier’s portfolio of completed commercial projects reveals whether they understand the real constraints of facility restrooms. When you evaluate potential partners, request specific examples from similar facility types-schools, gyms, corporate offices, or hospitality venues-and ask for contact information from at least three previous clients. Call these references directly and ask concrete questions: Did the supplier meet the promised timeline? Were there unexpected costs? How responsive was their team when issues arose after installation? A supplier who hesitates to provide references or offers only vague project descriptions typically lacks the commercial experience to handle your project smoothly.

Proven Track Record Across Commercial Projects

Your supplier’s completed installations speak louder than marketing claims. Request photos or site visits to facilities similar to yours, and verify that the supplier has handled projects at your facility’s scale and complexity. Schools demand durability and vandalism resistance; suppliers experienced in school restrooms understand grab bar placement, high-traffic wear patterns, and ADA compliance for student accessibility. Gyms and pools require suppliers who grasp moisture management and material selection for humid environments-a supplier recommending laminate for a pool facility signals inexperience. Corporate offices and hospitality venues need suppliers who balance aesthetics with durability, ensuring restrooms reflect brand standards without sacrificing longevity. When you speak with previous clients, ask whether the supplier proactively identified potential problems during the design phase or simply accepted the initial specifications without question. A supplier who caught compliance issues, suggested material upgrades for your facility type, or recommended layout adjustments demonstrates the expertise that prevents costly mistakes.

Transparent Pricing and Project Timelines

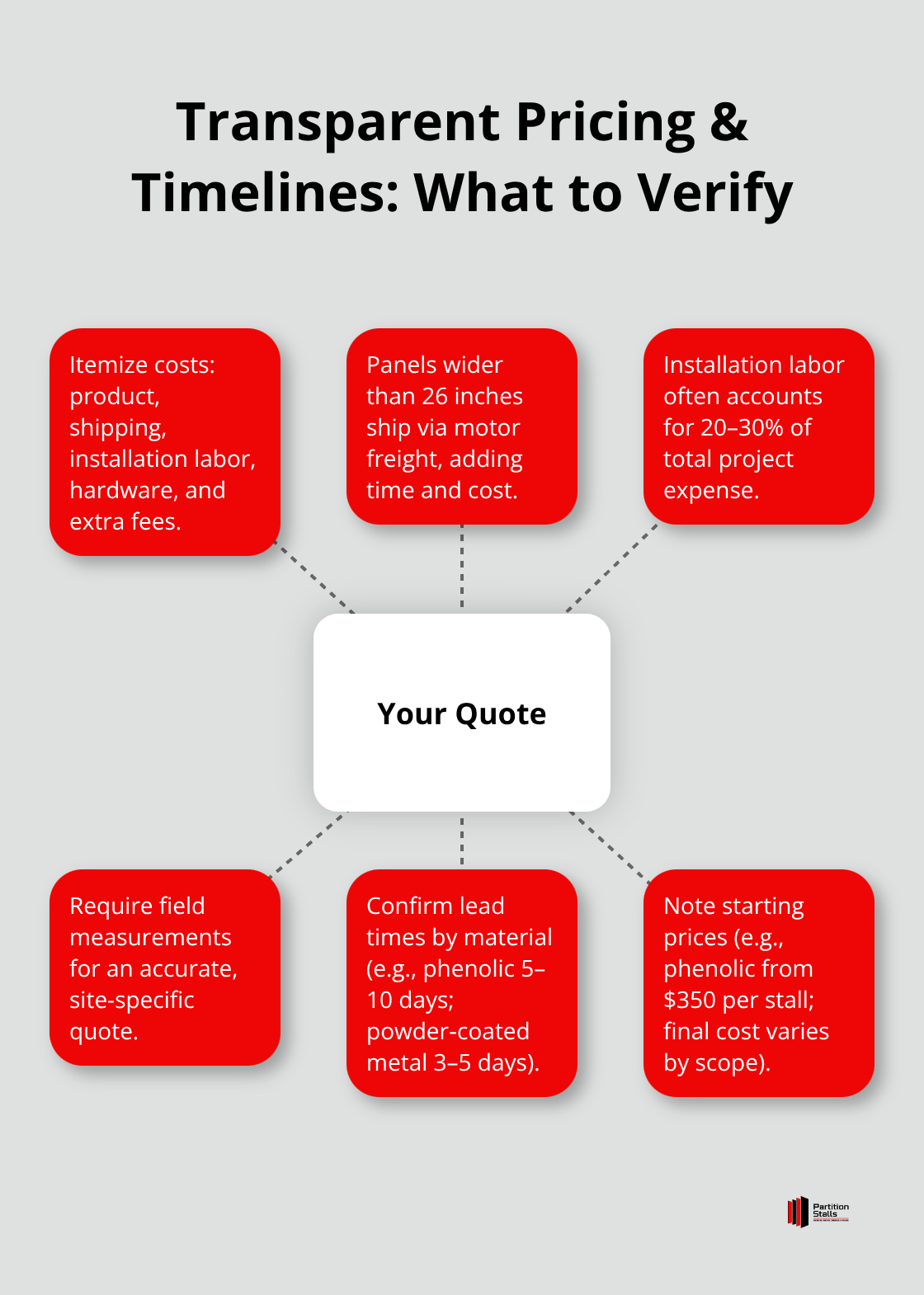

Transparent suppliers provide itemized quotes that separate product cost, shipping, installation labor, hardware, and additional fees. A quote listing only a unit price per partition masks the true project cost-shipping alone for panels wider than 26 inches requires motor freight rather than standard carriers, adding days to delivery and increasing costs significantly. Installation labor typically represents 20 to 30 percent of total project expense, yet many suppliers bury this figure or claim it varies based on site conditions without explanation. Request that your supplier conduct field measurements and provide a detailed quote based on your specific restroom layout, wall conditions, and accessibility requirements.

Lead times vary dramatically: phenolic partitions take 5 to 10 days depending on core type, while powder-coated metal ships in 3 to 5 days. A supplier who commits to specific delivery dates and explains how delays affect your project timeline demonstrates accountability rather than optimism. Compare quotes from multiple suppliers using identical specifications-same materials, dimensions, hardware, and installation scope-to identify genuine price differences versus hidden costs buried in vague line items. When you request quotes, ask whether the supplier includes site preparation guidance, compartment removal, and project management support or whether these services cost extra. Phenolic toilet partitions pricing begins at $350 per stall, with final costs dependent on mounting style and quantity.

Responsive Customer Service and Technical Expertise

A supplier’s responsiveness during the project and after installation determines whether they become a trusted partner or a source of frustration. Before you sign any agreement, confirm that installation includes a 1-year labor guarantee covering hardware adjustments, door alignment, and minor fixes without additional charges. Ask how the supplier handles urgent questions: Do they provide a direct contact for technical support, or do you navigate a phone menu? Request their typical response time for warranty claims and maintenance guidance.

Facilities operating in high-humidity environments like pools or gyms need suppliers who understand moisture management-they should proactively recommend materials suited to your conditions and explain why certain choices would fail. A supplier offering comprehensive maintenance guidance with specific cleaning product recommendations and schedules prevents costly damage from incorrect care. Verify that spare parts remain available for at least 10 years after purchase, since hardware failures or minor damage shouldn’t force complete partition replacement. When you evaluate potential suppliers, assess whether their technical team can answer detailed questions about material performance, ADA compliance, and custom configurations or whether they defer to sales staff who lack expertise.

Final Thoughts

Selecting the right toilet partition supplier requires evaluating material durability, customization capabilities, warranty coverage, installation support, and proven commercial experience. The cheapest bid rarely delivers the best value when you factor in replacement cycles, maintenance costs, and facility downtime. Phenolic and stainless steel partitions cost more upfront but eliminate the expense of premature failure that plagues budget alternatives.

We at Partition Stalls understand that facility managers need more than products-they need a partner who handles the entire process from design through installation and beyond. Our team provides expert guidance to match materials and configurations to your specific facility type, traffic patterns, and compliance requirements. We conduct field measurements, design restroom layouts with ADA compliance built in, and manage installation with professional crews who understand partition-specific requirements.

Contact us for a free consultation to discuss your restroom project, and we’ll evaluate your facility type, traffic volume, moisture exposure, and budget constraints to recommend materials and configurations that deliver long-term value. Visit Partition Stalls to explore our product range and request a detailed quote based on your specific requirements. Your restroom investment should reflect your facility’s standards and serve your users reliably for years to come.