Toilet partition latches might seem like a minor detail, but they directly impact user experience and facility maintenance costs. The wrong choice leads to frequent repairs, security issues, and frustrated visitors.

We at Partition Stalls see facilities struggle with latch failures that could have been prevented with proper selection. The right latch type depends on your specific partition material, usage patterns, and budget constraints.

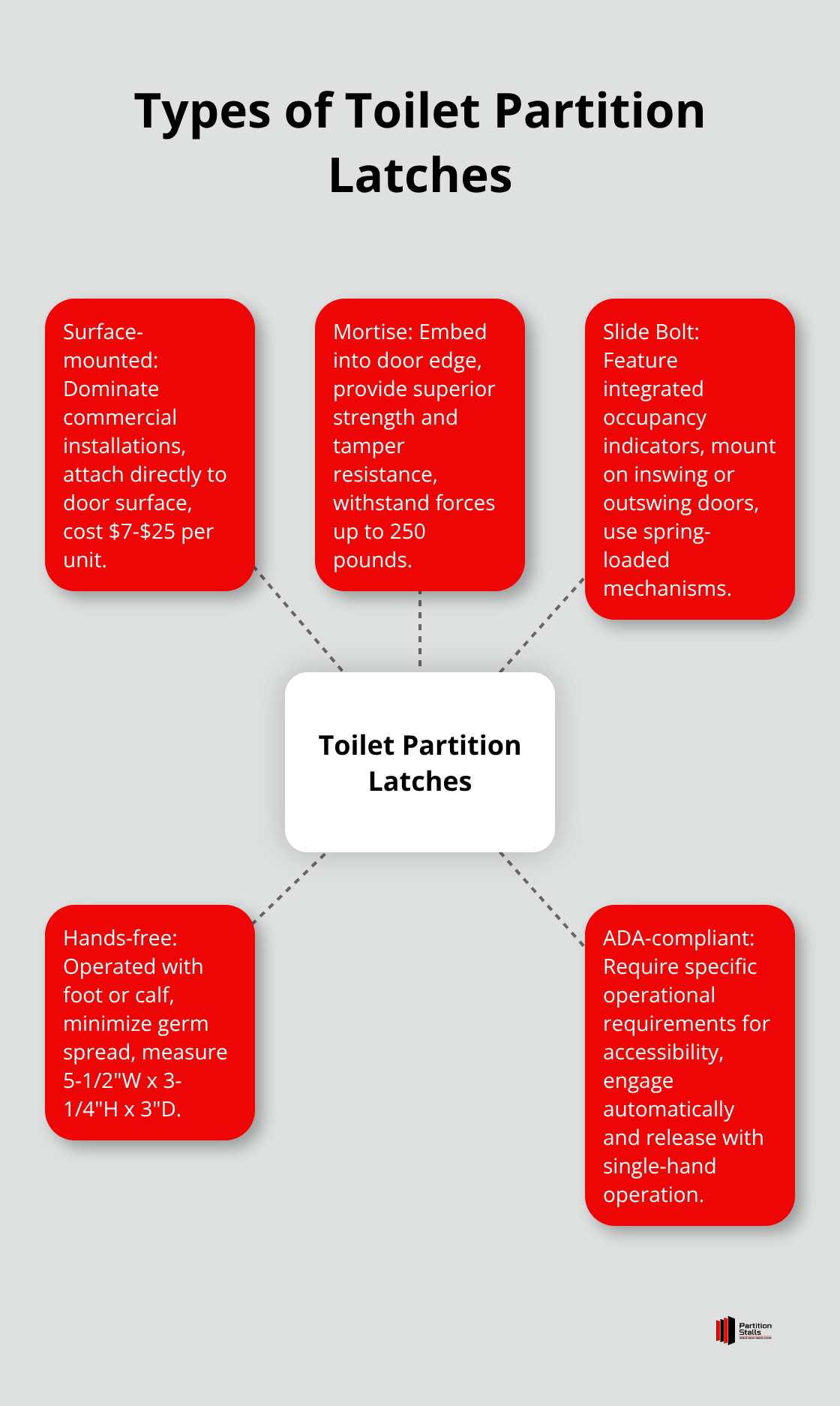

Which Latch Types Work Best for Commercial Restrooms

Surface-mounted latches dominate commercial installations because they attach directly to the door surface without cuts or modifications. These latches work with doors from 3/4-inch to 1-inch thickness and cost between $7-$25 per unit based on material quality. Chrome-plated brass versions offer the best value for moderate-traffic areas, while cast stainless steel handles heavy-use facilities like airports and stadiums. Installation takes 10-15 minutes per door with basic tools, and replacement parts remain available from manufacturers like Accurate Partitions and Global Partitions.

Mortise Latches for Maximum Security

Mortise latches embed into the door edge and provide superior strength and tamper resistance compared to surface options. These mechanisms require precise cuts during installation, which adds $15-30 per door in labor costs, but deliver unmatched durability in high-security environments. Heavy-duty mortise systems withstand forces up to 250 pounds and meet strict institutional requirements for detention facilities and psychiatric hospitals. The recessed design eliminates hardware that vandals target, while stainless steel construction resists corrosion in humid conditions.

Slide Bolt Systems for Occupied Indicators

Slide bolt latches feature integrated occupancy indicators that display red when locked and white when available, which reduces awkward door-testing by users. These mechanisms mount on either inswing or outswing doors with adjustable keeper positions to accommodate various partition alignments. Commercial-grade slide bolts use spring-loaded mechanisms that automatically return to the unlocked position and prevent doors from staying secured accidentally. Aluminum versions work perfectly with HDPE partitions (lightweight yet robust), while stainless steel options complement phenolic and laminate installations in medical facilities where hygiene standards demand non-porous surfaces.

Hands-Free Options for Hygiene Control

Hands-free latches allow users to operate doors with their foot or calf, which minimizes germ spread in high-traffic restrooms. These mechanisms measure 5-1/2″W x 3-1/4″H x 3″D and include all fasteners with straightforward installation instructions. Chrome-plated brass and cast stainless steel construction offers enhanced durability for facilities that prioritize both hygiene and longevity. The foot-operated design works particularly well in healthcare settings and food service establishments where contamination control matters most.

Material selection plays an equally important role in latch performance and longevity, which directly affects your facility’s maintenance budget and user satisfaction. Quality hinges, locks, and brackets contribute significantly to the overall durability and functionality of your bathroom stalls.

What Determines Latch Performance and Longevity

Material selection separates reliable latches from frequent failures in commercial restrooms. Stainless steel construction costs more than chrome-plated alternatives but delivers longer service life in high-humidity environments. Cast stainless steel components resist corrosion better than stamped versions, while chrome-plated brass offers excellent value for facilities with moderate moisture exposure. Aluminum hardware works best with HDPE partitions but shows weakness in salt-air coastal locations where corrosion accelerates rapidly.

Security Standards Match Facility Risk Levels

High-security environments like detention centers require mortise latches that withstand 250-pound forces, while standard commercial facilities operate effectively with surface-mounted systems rated for 150-pound loads. Privacy indicators reduce user frustration by 30% according to facility management surveys, which makes slide bolt systems worthwhile investments for customer-facing restrooms. ADA-compliant latches require privacy latches and specific operational requirements for accessibility. Security screws add $2-3 per latch but prevent vandalism in unsupervised areas (parks and transit stations need this protection most).

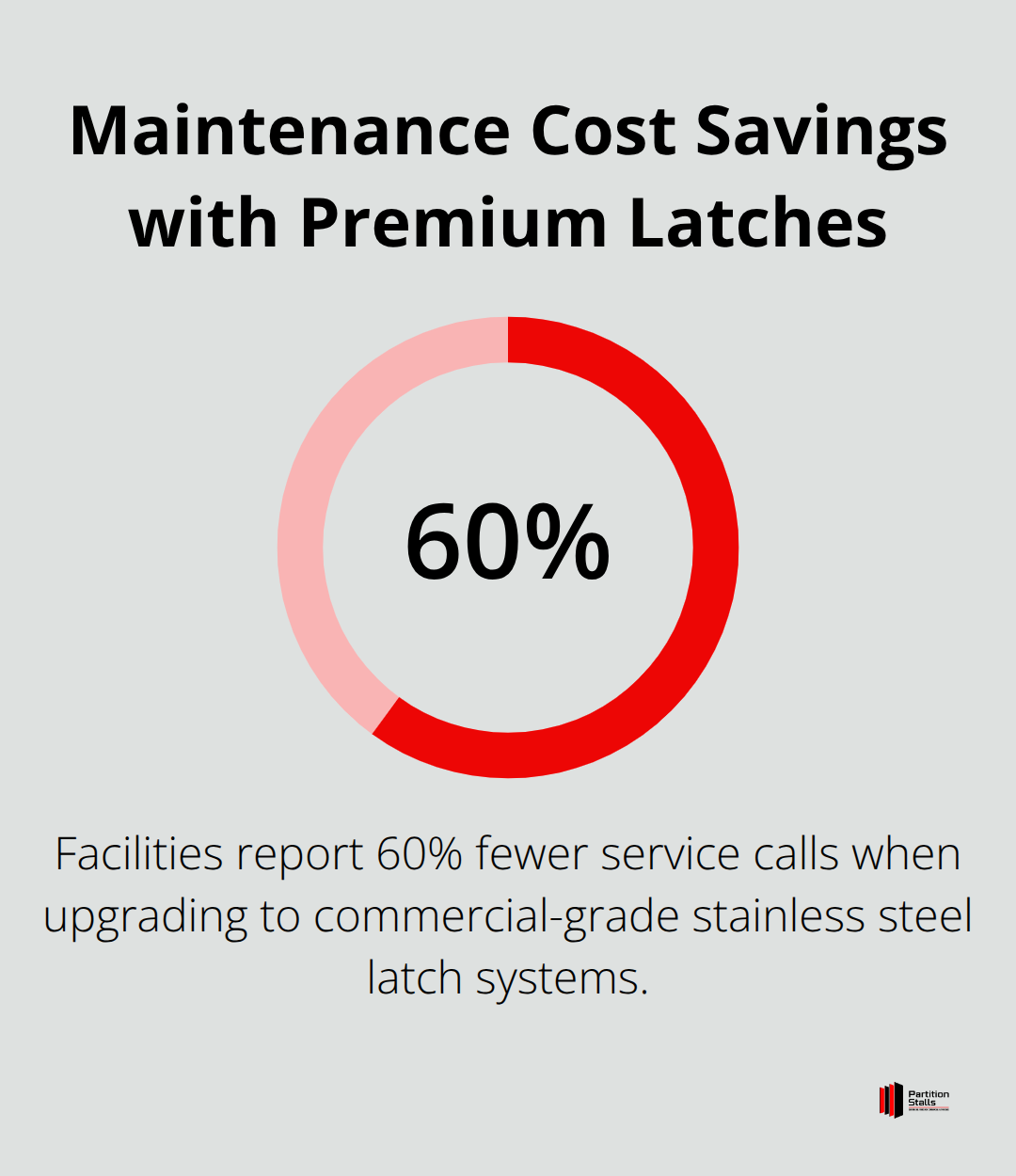

Maintenance Costs Reveal True Value

Premium latches with sealed mechanisms require lubrication every 18-24 months compared to basic models that need attention every 6-8 months. Replacement parts for major manufacturers like Accurate Partitions and Global Partitions remain available for 10+ years, while generic hardware often becomes obsolete within 3-4 years. Labor costs for latch replacement average $25-40 per unit with parts included, which makes durability the primary factor in total ownership costs. Facilities report 60% fewer service calls when they upgrade from economy latches to commercial-grade stainless steel systems (this translates to substantial savings in high-traffic installations).

Your partition material and door specifications will determine which latch types work best with your specific installation requirements. Essential hardware components ensure the longevity and performance of your complete partition system.

How Installation Requirements Affect Latch Selection

Partition material thickness determines latch compatibility more than any other factor. Laminate partitions at 1-inch thickness work with standard surface-mounted latches that use 2-3/4-inch screw spacing, while phenolic panels require specialized hardware due to their dense composition. HDPE partitions need aluminum latches to prevent galvanic corrosion between dissimilar metals, and stainless steel systems demand matching stainless components throughout the installation. Powder-coated steel partitions accept chrome-plated latches effectively, but mixed materials create weak points where moisture penetrates at different expansion rates. Facilities save 40% on replacement costs when they match latch materials to partition composition from the initial installation.

Door Weight Limits Determine Mechanism Strength

Heavy phenolic doors that weigh 25-30 pounds require mortise latches with reinforced keeper plates, while lightweight HDPE doors at 12-15 pounds operate smoothly with standard surface hardware. Oversized doors that exceed 32 inches width need ADA-compliant mechanisms. Cast stainless steel latches handle doors up to 40 pounds without sagging, but stamped versions fail under 25-pound loads within 18 months of installation. Accurate measurements prevent costly retrofits when door weight exceeds latch capacity ratings (this applies especially to phenolic installations).

Material Compatibility Prevents Corrosion Issues

Chrome-plated latches work best with powder-coated steel and plastic laminate partitions, while stainless steel hardware matches stainless steel partition systems. Aluminum components pair exclusively with HDPE partitions to avoid electrochemical reactions that cause premature failure. Mixed metal installations create galvanic cells where moisture accelerates corrosion at connection points. Manufacturers like Accurate Partitions and Global Partitions specify exact material combinations to prevent these compatibility issues.

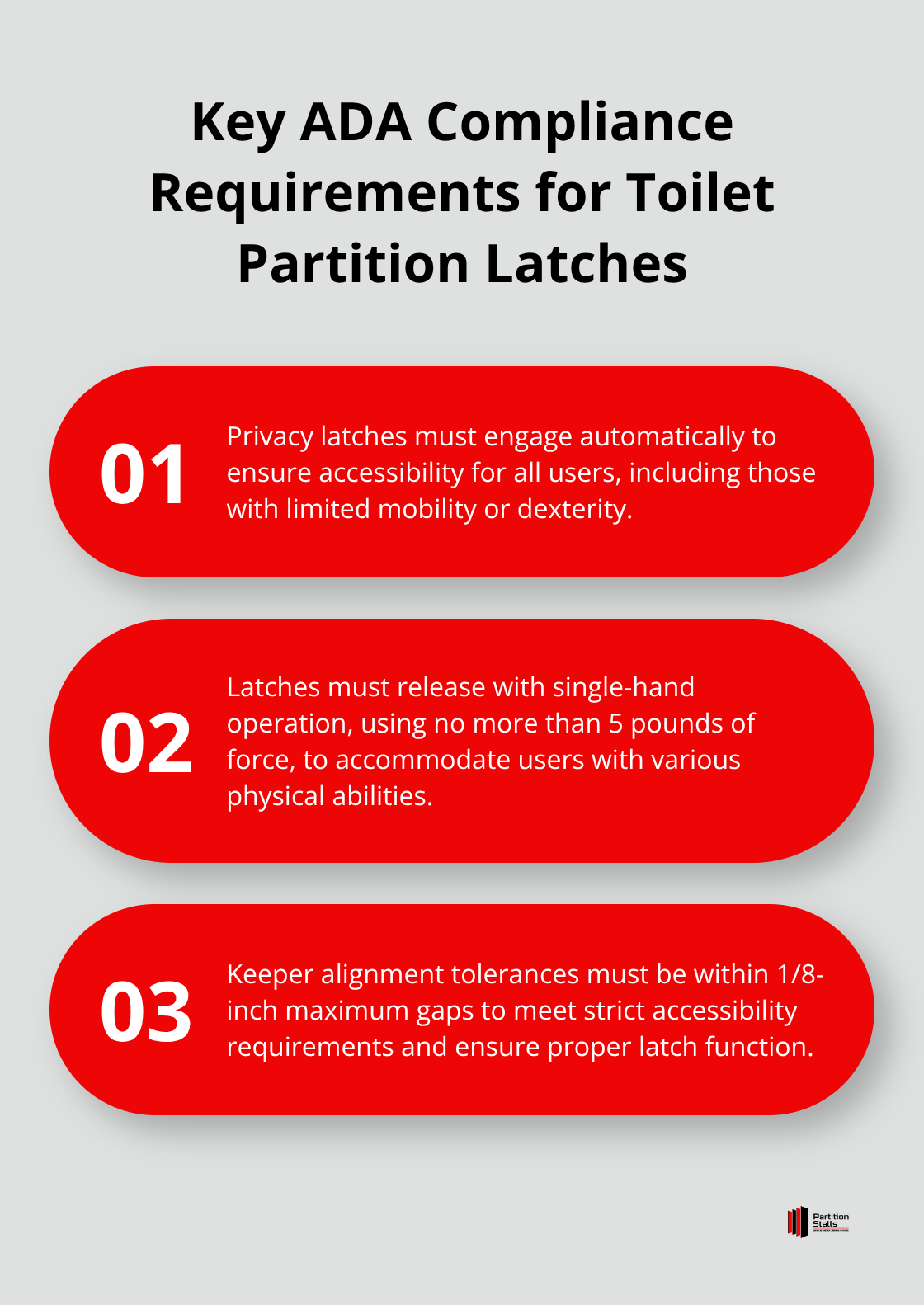

ADA Standards Override Design Preferences

Accessible compartments require offset door positions and specific latch operations that standard hardware cannot accommodate. Privacy latches must engage automatically and release with single-hand operation that uses no more than 5 pounds of force. Occupancy indicators become mandatory for accessible stalls to prevent users from attempting entry when occupied. Keeper alignment tolerances tighten to 1/8-inch maximum gaps to meet accessibility requirements, which eliminates many economy latch options that allow wider variances. Professional installers charge $15-25 more per ADA-compliant latch due to precise adjustment requirements (standard installations skip these detailed specifications).

Final Thoughts

Toilet partition latches must match your facility’s specific demands to deliver reliable performance. High-traffic environments benefit from cast stainless steel mechanisms that withstand 250-pound forces, while moderate-use facilities operate effectively with chrome-plated options at half the cost. Material compatibility prevents premature failures that plague mixed-metal installations.

Long-term performance data shows premium latches reduce maintenance calls by 60% compared to economy alternatives. Facilities save $200-400 annually per restroom when they invest in commercial-grade hardware initially rather than replace failed components repeatedly. ADA-compliant installations add $15-25 per latch but prevent costly retrofits later (professional installation matters more than many facility managers realize).

Precise keeper alignment and proper torque specifications extend latch life significantly. Misaligned hardware fails within 12-18 months regardless of quality levels. We at Partition Stalls provide comprehensive restroom solutions that include expert guidance on toilet partition latches and professional installation services.